Membrane Layer Switch Over Technology: The Trick to Reliable and Cost-Effective Interfaces

Membrane layer switch modern technology has emerged as a pivotal part in the style of user interfaces, giving both integrity and cost-effectiveness throughout a diverse range of applications. As we discover the multifaceted benefits of membrane buttons, their possibility for technology increases questions regarding future applications and developing trends.

Understanding Membrane Layer Change Technology

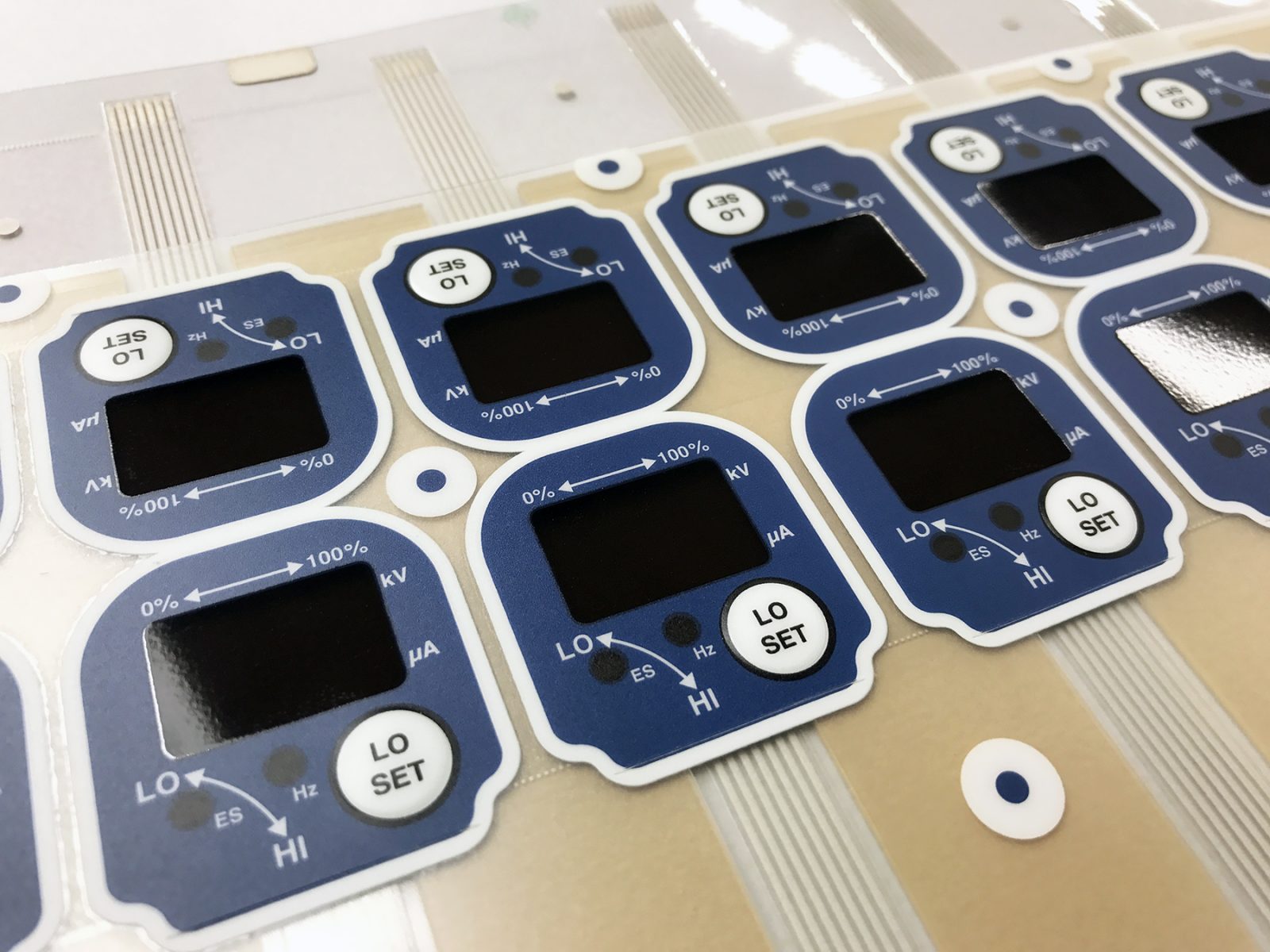

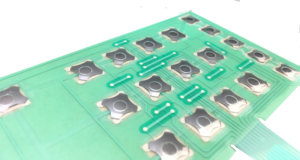

Membrane layer switch modern technology is an extensively used user interface solution in numerous electronic gadgets, offering a smooth mix of performance and layout. This innovation includes multiple layers of products, usually being composed of a visuals overlay, spacer layer, and a circuit layer. The visuals overlay displays the user interface aspects, while the spacer layer divides the circuit layer from the overlay up until a customer activates a button.

When stress is applied to the overlay, the circuit layer completes the electric circuit, sending a signal to the device. This device allows for different arrangements, consisting of responsive feedback and backlighting alternatives, boosting user interaction. Membrane layer buttons are typically produced making use of durable materials such as polyester or polycarbonate, making sure long life and resistance to ecological factors like moisture and dust.

The adaptability of membrane layer switches over allows their application in diverse markets, consisting of clinical tools, customer electronic devices, and industrial controls. Their portable design enables combination right into space-constrained atmospheres, giving a reliable individual interface without endangering visual allure. Recognizing the intricacies of membrane layer button technology is crucial for makers and designers seeking to create trustworthy and efficient human-machine user interfaces.

Secret Benefits of Membrane Switches

While numerous user interface remedies exist, membrane layer switches over deal unique advantages that make them a preferred choice in many applications. Among the main benefits is their resilience; membrane buttons are made to hold up against harsh ecological conditions, including dampness, dirt, and temperature fluctuations, guaranteeing resilient performance. This resilience considerably decreases the need for regular replacements, therefore reducing overall upkeep expenses.

Moreover, membrane layer buttons are lightweight and compact, making them ideal for applications where room is limited. Their inconspicuous design contributes to a streamlined look without compromising performance.

Cost-effectiveness is additionally a noteworthy advantage, as the production procedure for membrane layer switches over tends to be cheaper contrasted to typical mechanical buttons. This affordability, incorporated with their dependability and convenience of installment, positions membrane layer switches as a useful service for a wikipedia reference large range of sectors looking for reliable and reliable customer interfaces.

Applications Throughout Numerous Industries

How do membrane switches adapt to the varied needs of various markets? Membrane switch modern technology is increasingly recognized for its flexibility, making it suitable for a variety of applications across multiple industries. In the medical area, membrane layer buttons are used in diagnostic equipment and patient tracking devices, where their longevity and convenience of cleaning are vital for preserving health requirements. The automobile industry uses these buttons in dashboards and control board, providing a streamlined visual while making certain easy to use operation.

In consumer electronic devices, membrane Click Here buttons supply a compact service for remote controls and home devices, enhancing customer experience with instinctive style. Furthermore, the industrial market leverages membrane buttons for machinery control panels, gaining from their resistance to extreme settings, such as dampness and dirt.

Armed forces and aerospace applications additionally utilize membrane buttons for their dependability and ability to hold up against extreme conditions, guaranteeing operational effectiveness in critical situations. In addition, the food and beverage market embraces these buttons for automated systems, where sanitation and simplicity of procedure are critical. Eventually, membrane layer buttons are customized to meet the distinct demands of each market, verifying their vital duty in modern technology interfaces

Design and Personalization Choices

In the realm of membrane layer button technology, design and customization alternatives play an essential duty in boosting capability and customer communication. These buttons can be tailored to meet details functional needs and visual preferences, making them flexible elements in various applications.

One of the main modification alternatives is the format of the button itself, which can be developed to accommodate unique interface and ergonomic factors to consider. By readjusting the form, size, and setup of switches, makers can produce intuitive styles that promote ease of use. Additionally, the incorporation of various colors and graphic overlays enables branding and enhanced exposure, ensuring that customers can swiftly identify functions.

Furthermore, membrane layer switches can be crafted with different tactile responses systems, such as increased buttons or distinct clicks, to enhance the customer experience. Different products can likewise be picked for longevity and ecological resistance, attending to factors such as dampness, temperature variations, and chemical exposure.

Inevitably, the substantial style and customization choices available in membrane button technology encourage businesses to produce tailored remedies that not only satisfy functional demands yet likewise align with their branding and functional demands.

Future Trends in Membrane Buttons

As membrane layer switch innovation proceeds to advance, future trends are progressively concentrated on improving customer experience and integrating advanced performances. One substantial fad is the assimilation of touch-sensitive and capacitive technologies into conventional membrane layer buttons. This development allows for more user-friendly customer interfaces, giving tactile comments while keeping a streamlined layout.

An additional arising fad is making use of eco pleasant products, driven by the expanding need for lasting production techniques. Makers are looking for to reduce their carbon footprint by utilizing recyclable substrates and low-impact inks, straightening with international sustainability objectives.

In addition, click here to find out more the surge of the Internet of Things (IoT) is prompting the unification of clever functions right into membrane switches. Boosted connection alternatives will enable devices to communicate with each various other, permitting seamless combination into broader systems.

In addition, advancements in printing modern technologies, such as electronic printing, are enabling greater design adaptability and modification. This allows producers to produce intricate layouts and lively colors cost-effectively.

Conclusion

In verdict, membrane switch modern technology stands for a crucial innovation in customer interface style, providing substantial benefits in durability, modification, and cost-effectiveness. As improvements proceed to emerge, specifically in touch-sensitive user interfaces and sustainable materials, the capacity for membrane switches to boost individual experience and capability remains encouraging.